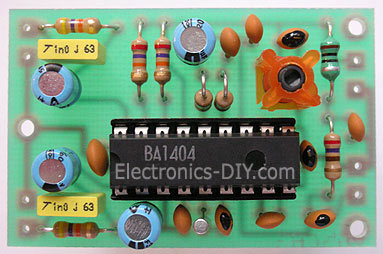

The heart of any electronic project is the PCB. Without a proper PCB, a project may end up in total failure.

A perfect PCB · gives a face lift to the appearance and performance of the circuit and, what is of greater importance, its neatness facilitates easy troubleshooting. As soon as a project is taken up, the first thing that comes to the mind is a ready made PCB. When it is not avail- able, the universal veroboard (VB) is substituted by many hobbyists and some professionals too! An easy way to make 1 a PCB is described here.

Materials required

1. Hand drill

2. Electric drill

‘ 3. Drill bits 0.8 mm and 3 mm

4. Minor hacksaw

5. Rat tail file

6. Clamp

7. Enamel paint (can be left out if

PCB pen is available)

8. Fine painting brush (pointed tip)

(can be left out if PCB pen is available)

9. Ferric chloride

10. Veroboard (VB) with 0.1 inch

spaced array of holes

11. Copper clad board (CCB)

12. Transparent foot rule.

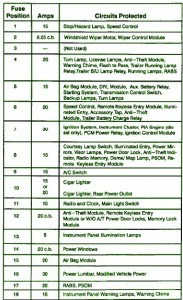

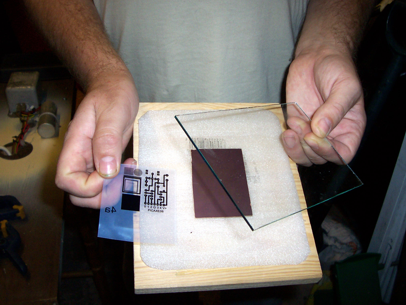

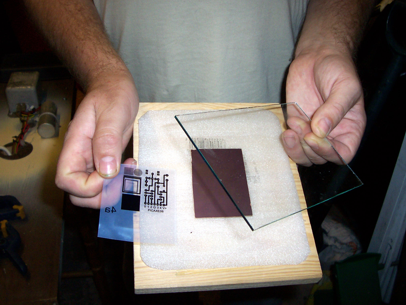

Gather all the components needed for the project. In the case of ICs, use IC base for all. Bend the leads of all the components according to their sizes and mount them on the VB, as far as possible, in identical position as in the circuit. Remember to leave enough space around each component, for the copper tracks pass around them in parallel fashion on the other side of the board. Give serious consideration to this point when there are ICs. In short, spread out the components. The holes through which the leads of the components are protruding should be marked using an ordinary pencil (which can be rubbed off or erased after finishing the PCB project). The above procedure determines the size of the copper clad board (CCB) required for the project. CCB of the required size can be purchased or cut off from a bigger piece. The vertical and horizontal centre lines separating the CCB into four segments may be drawn on the copper foil using the transparent foot rule and a sharp needle applying light pressure.

Place the VB on theCCB such that thc copper foil on thc CCB and the pencil markings on the VB are facing up. The CCB must .be adjusted to be exactly at the centre of the layout on the VB. This can be achieved by looking through the VB matrix to locate the centre lines drawn on the copper foil of the CCB. The board pair can then be placed on a wooden plank and the clamp may be used to secure them tight before drilling. A more sophisticated clamp can be used after gaining some experience with this small gadget.

Electric PCB drilling machines are quite expensive. A manually operated drill would suffice for an electronics hobbyist. But for people who want to make this job less tiresome, here is a simple way to make a PCB driller. The normal sewing machine motor or a similar high RPM motor with a regulator foot control is ideal. Remove the V- belt, clamps and pulley. Procure a double end jaw mouth from a watch repair shop and cut exactly at the centre, using a hacksaw. Attach one end of the jaw to the shaft of the motor. A careful scrutiny of the motor and the jaw mouth is required to get the drill bit exactly at the centre. This device can take up drilling of 0.8mm holes for ICs at precise dimensions and spacings.

Hold the motor of the above device (or hand drill) and start drilling. The drill must never be allowed to rest on the drill bit as it will definitely snap under pressure. Drill the CCB through the VB at all the pencil markings made on the VB. A few minutes of practice would give an idea about the amount of control needed on the foot regulator and also the extent of pressure to be allowed to rest on the drill bit, while the shaft is revolving at high speed. To avoid waste material or debris coming out of the CCB through the VB holes, a half depth drill on PCB may be made throughout and later drilled to the full depth without the VB. This will prolong the life of the VB without damaging its holes and also save the trouble of blowing out the debris at short intervals while looking for pencil markings.

When the drilling is complete, try to imagine the circuit on a paper as it should appear on the copper side. Trial tracks may be drawn using a pencil from one hole to the other. The most efficient, shortest possible layout with least likely interference due to inter- track capacitance, induction, etc may be arrived at. The tracks should not have sharp corners and must be wide enough for the current they carry.

It is highly probable that while trying out the circuit, two separate tracks may cross one another without any short between the two. This can be avoided by the use of jumpers (wires placed on the component side of the board). The l position of the holes for the jumpers- may be placed conveniently on the copper side without trespassing into another component on the component side. The position of these holes must be made stable for the drill bit by ‘centre punching’, using the sharp tip of the rat tail file. Never try drilling the CCB without the punch mark because in the absence of the VB, the drill bit has the tendency to drift fast and break as soon as the regulator is pressed. The copper foil may also get damaged by the drifting drill bit.

The jumpers must be parallel and non-overlapping to facilitate assembly. When there are too many jumpers, as in the cmse of multi-lead components like microprocessor ICs, double sided PCBs are the only solution.

Holes must be drilled along one or more edges according to the require- ments and convenience for power sup- ply, input, output and interstage connections, if any. For securing the PCB on any cabinet, use 3mm drill bit at convenient points on the CCB, usually the four corners.

Instead of a PCB pen, a fine tipped brush is used to apply a thin coat of enamel paint lines on the pencil tracks to complete the circuit. A small blob of paint may be applied to each drill hole so that the etchant does not eat away the copper at the crucial soldering points. This blob gives the advantage of producing a perfect circular copper terminus on each hole. If a track is wrongly drawn with paint, it is better to leave it y there to dry up and then remove it using a razor blade or knife. Wet paint, when removed using a cloth, leaves behind a thin transparent coat of the enamel which prevents etching at that point. The paint should not be allowed to dry up completely as it becomes very difficult to remove it after the etching process. The unused portion of the copper on the CCB may be painted without touching other tracks and connected to the main ground. Conditions like interference, ground loop, etc should be considered before finishing the painting work.

he CCB with half dried paint immersed in a solution of ferric chloride (containing a few drops of concentrated hydrochloric acid to prevent precipitation of ferric hydroxide). A plastic tray, porcelain or glass plate would be ideal for storing the solutions. Depending on the concentration of the etchant, etching time may vary. When etching is over, the paint should be wiped off with a cloth dipped in kerosene. Hard dried paint may be removed by using acetone. The drill may again be used to clean the holes which may have been clogged by the paint. Soon after etching and cleaning, soldering of the components should be taken up. If this is delayed, oxidation of the copper film may lead to difficulty in Soldering.

Resistors:

Resistors: